| Home | Products | Training | Support | About Us | Contact | |||

|

|

|

|

Available in 3 Editions

Predator CNC Editor is bundled with Predator DNC Express, DNC, DNC Enterprise and Virtual CNC. The bundled version includes all features of the stand-alone edition less all DNC features. FEATURES

CNC Intelligent Editing with Undo and RedoDozens of CNC intelligent editing commands make changes to your CNC program quickly and easily. Edit confidently with the ability to undo and redo all changes. Microsoft® Word compatible menus, toolbar and shortcut keys make Predator CNC Editor easy to learn. Unlimited File SizeThe Predator CNC Editor supports up to 64 Megs of code per CNC program. In addition, editing multiple CNC programs at the same time is supported, with the ability to cut, copy and paste between them. File CompareThe Predator CNC Editor includes a side by side file compare which identifies each G and M code difference and fixes them with a single click of the mouse. A summary report and numerous options to ignore spaces, blank lines, leader/trailer, feed rates, spindle speeds and tool changes simplify the process of integrating shop floor edits with a master CNC program. DNC Send, Receive and Dripfeed to your CNC machinesSend, receive and dripfeed to one machine at a time, via switch box or direct connection to any compatible CNC machine. Works in the background

even while other software applications are running. Should a tool break, an easy to use DNC Restart command automatically re-creates the CNC

program from any point. (NOTE: An upgrade to the Predator DNC product provides support for DNC networking of multiple

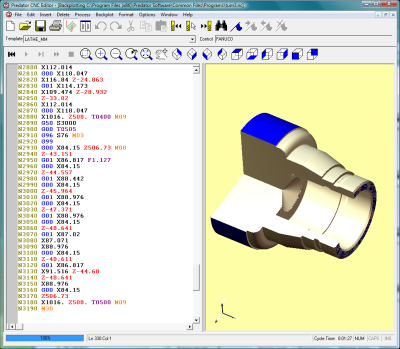

3D Backplotting and Verification of your CNC CodeGraphically verify CNC code by quickly backplotting a wire frame model of any CNC program in a true 3D environment. Supports 2-, 3- and 4-axis mills, routers, waterjets, lasers and lathes. Within the graphics window eight predefined views, zoom in, zoom out, pan and fit commands provide complete control of the process. Copy the backplot or 3D animation to the clipboard and quickly add graphics to your setup sheets. For best results, 3D backplotting and verification often requires appropriate machine and reverse post processor configuration. NOTE: Complex (4- and 5-axis) mills and mill/turn lathes require Predator Virtual CNC for backplotting and verification. An upgrade to our full Predator Virtual CNC product provides support for comprehensive CNC verification and full machine simulation. CNC TemplatesPredator Editor CNC Templates add intelligence by remembering all the CNC control details. Includes a library of 20 sample CNC templates. Each CNC template is completely configurable. |

Copyright © 2009, EDA Solutions. All rights reserved. |

|

|||||||

Each Predator CNC Editor license can be customised to

address the unique requirements of each manufacturer.

Each Predator CNC Editor license can be customised to

address the unique requirements of each manufacturer. CNC machines at the same time.)

CNC machines at the same time.)